The cold weather has finally arrived, yet amidst the dropping temperatures, we invite you to step into the warmth of ThermALab. This December, we want to take you on a tour of the Department of Energy’s ‘laboratory of heat’, founded and coordinated by Professor Alfonso Niro.

Experiments related to heat transfer, often accompanied by numerical modelling, are conducted here. Analyses of heat loss and energy consumption, spectrophotometric measurements of optical properties in the UV-Vis-IR range, spectral characterisation of light sources, thermal conductivity measurements, IR thermographic analyses. These are all examples of some of the activities we will try to illustrate,.

Or rather, that Damiano Fustinoni, who is involved in both research at ThermALab and teaching in two Technical Physics courses, will illustrate. This is also an excellent opportunity to learn more about the specialist’s role, which is perhaps not widely known outside the departments.

What activities do you carry out at ThermALab?

The research team consists of 6-7 people who are closely associated with ThermALab, four of whom work there permanently.

In our laboratory, we mainly deal with thermal analysis and heat transfer. This involves both basic and applied research on the phenomena of conduction, convection and radiation.

We work on some well-established lines of research within our group. We also carry out collaborative work with other research groups at Politecnico or with other universities, but we also carry out consultancy work and research activities that are contracted by companies.

What are the differences between basic and applied research?

I am involved in basic research, which I love and has become an integral part of me and my way of seeing things. Basic research, with its long-term benefits, is approached with an expansive perspective that extends infinitely, with immediate industrial applications. It is the true forefront of research, and I find it truly fascinating.

Of course, we also do applied research in our laboratory, often answering questions or industrial problems that require analysis and academic expertise to achieve quick solutions. We also develop and assess many numerical models with experimental data.

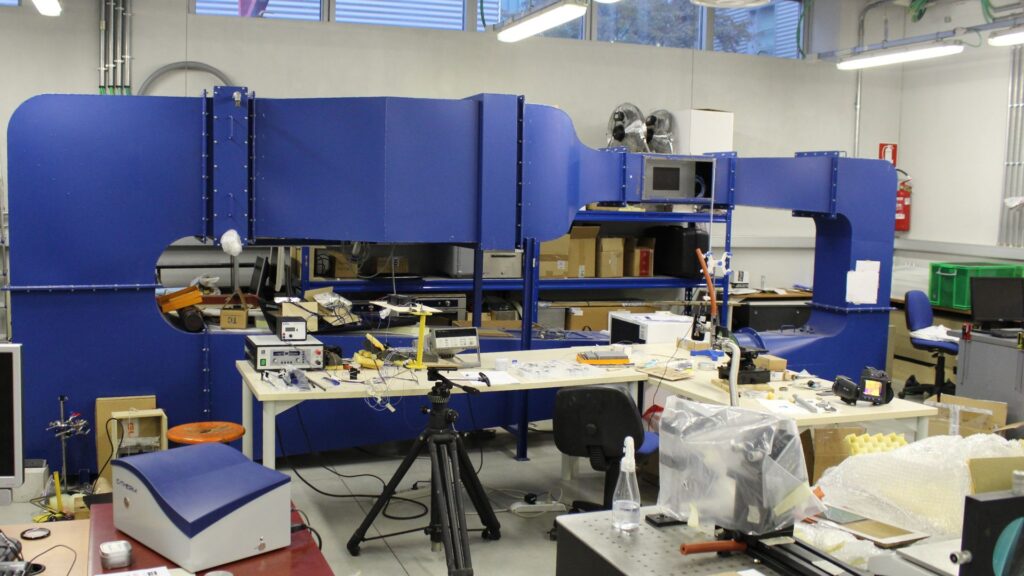

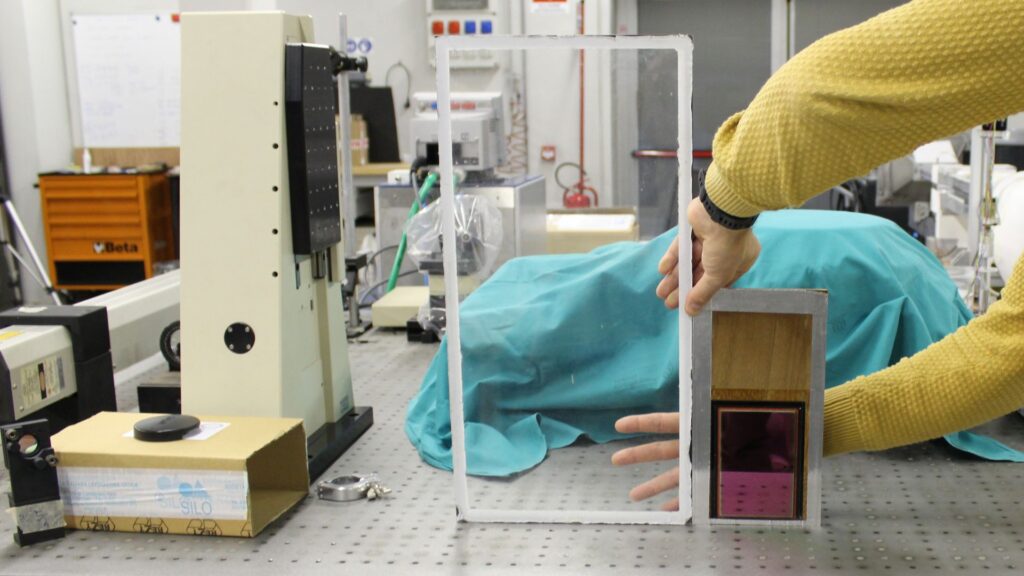

Tell us what this laboratory is like

As you can see, it can be chaotic [laughs] and this is indeed functional to research. Despite the chaos, research brings order and gives the world a common thread, right?

The laboratory tables have become like islands, each with their own machinery and specialised tasks. The laboratory is like an archipelago: the tables are like islands that communicate with each other, they are not isolated islands.

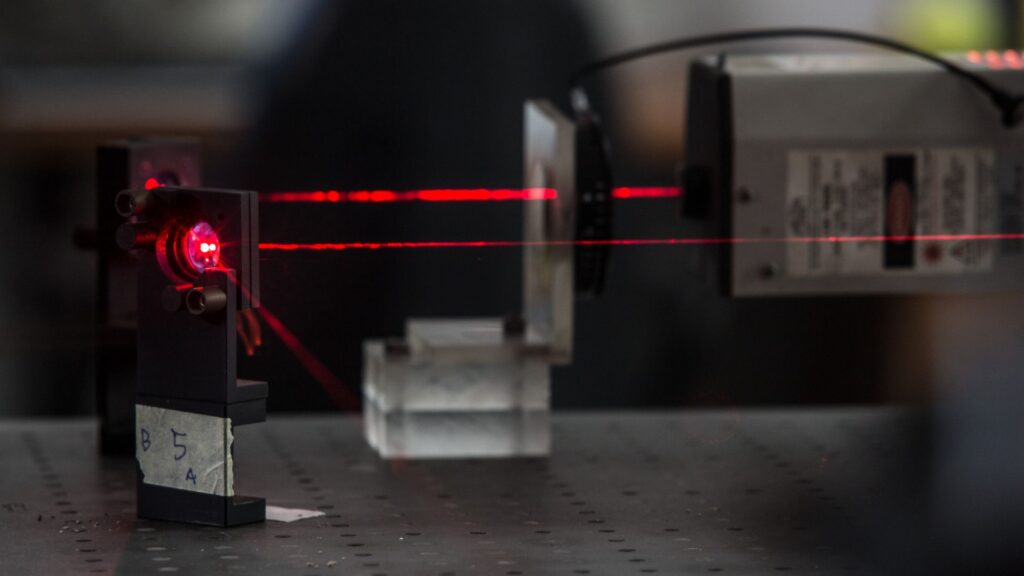

These tables are equipped with various types of machinery related to light and heat radiation: the UV-Vis-NIR spectrophotometer with various accessories that measure a range of optical properties of surfaces. That other, small instrument opens up new avenues for conducting a variety of measurements in the mid-infrared spectrum.

How does the UV-Vis-NIR spectrophotometer work?

Firstly, the spectrophotometer is an instrument that measures the amount of radiation transmitted or reflected by a surface. The difference between what is transmitted and what is reflected indicates the amount of radiation that has been absorbed by the object.

Over the years, we have succeeded in equipping the laboratory with several components that allow the spectrophotometer to characterise various optical properties of materials, which are necessary for developing accurate numerical models and for designing experiments where irradiation is involved.

In this case, we use the spectrophotometer for collaborative research projects with space agencies. In a vacuum, heat transfer occurs solely through radiation. We use the spectrophotometer to measure how materials reflect and transmit radiation. From these measurements, we can also derive absorbance and emissivity.

Can you give me an example of when these machines are used?

Once, we did a big job in collaboration with a thesis student in Architecture. The aim of the project was to develop a system of films that could be applied to glass panes to increase energy savings. The idea behind the system was to allow visible light to pass through the films during summer, while blocking thermal radiation, and allow thermal radiation to pass through during winter. The work from that thesis resulted in the creation of a patent that a leading company in the transparent surface production industry asked us to evaluate.

What I like is that these devices often become tools to open up to other areas at Politecnico. The University has been very forward-thinking about this: there have been huge strategic investments to finance collaborations and encourage cross-overs between various areas of expertise that go beyond specific affiliations between departments.

What are these called?

This is the ARTA, and is used for measuring the reflectance and two-way transmittance of materials at different angles of incidence of radiation and the response of the object in space. It is attached to the UV-Vis-NIR spectrophotometer, and it was developed in compliance with regulations related to the emissivity of glass, telescopes and objects intended for use in space.

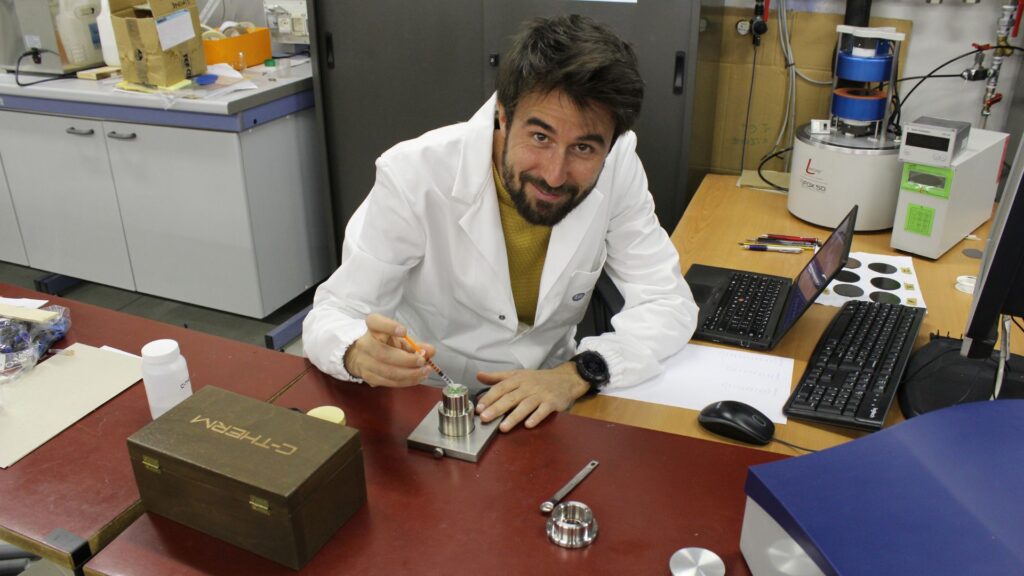

C-Therm and FOX 50 are instruments for studying the thermal conductivity of materials. We use the FOX50 for measurements on innovative materials, which do not often have a uniform composition throughout. These instruments have opened us up to research commissioned by companies and research that we carry out in collaboration with other research groups (for example, metal foams for energy applications), or research that we carry out with other departments (for example, with the Mechanics Department on loaded composites for automotive applications).

What does it do in this area?

It is dedicated to an ESA call won together through a collaborative effort involving the Department of Mechanics, Beamit and Leonardo.

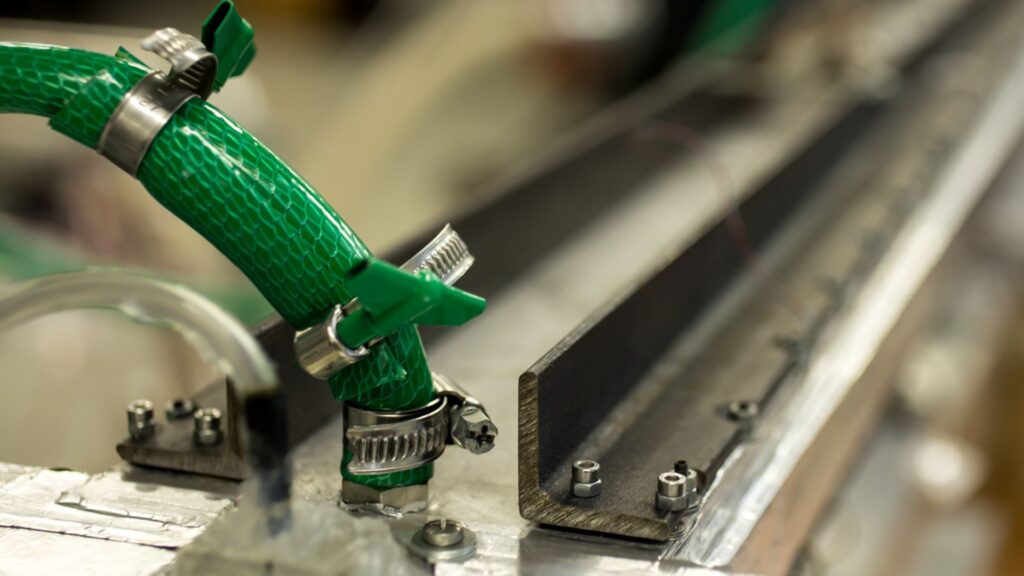

What you see are heat pipes that work with acetone, water or, in a few weeks, ammonia. They are superconductors of heat because they exploit the transition between states to efficiently transport heat. They are used to ‘transfer heat’ from the electronic components on satellite boards to other areas where the heat can be dissipated.

ESA has requested the creation of heat pipes using additive manufacturing techniques, like these you see here, that disperse very high amounts of heat energy. Once designed, we use Beamit to produce them and characterise them from a thermal point of view, in order to check whether they meet ESA’s requirements in terms of thermal efficiency and heat dissipation capabilities.

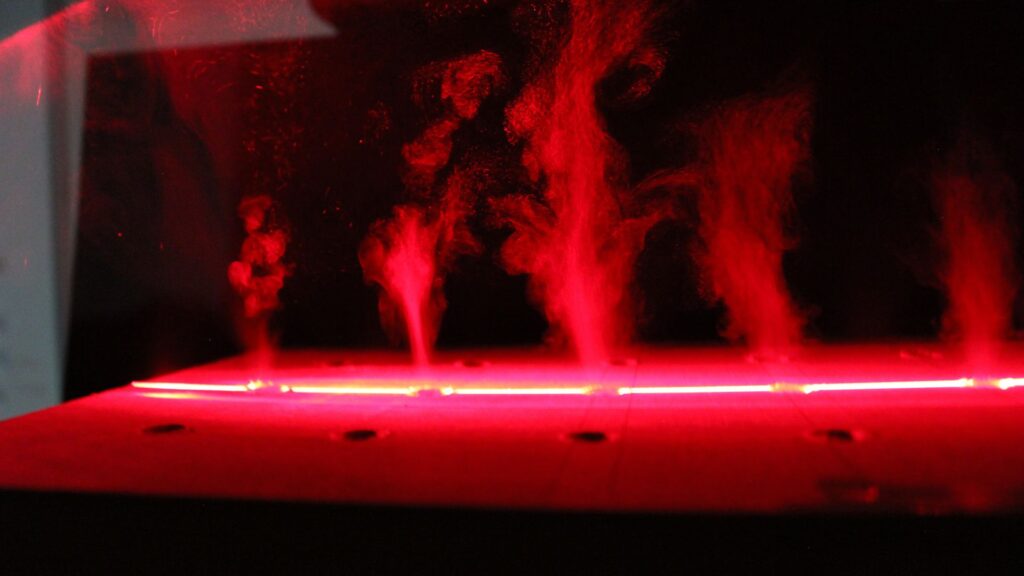

That one back there looks like a wind tunnel to me…

It is effectively a closed-circuit wind tunnel that characterises heat transfer in forced convection on a flat plate with different surface structures. This was the subject of my degree thesis many years ago.

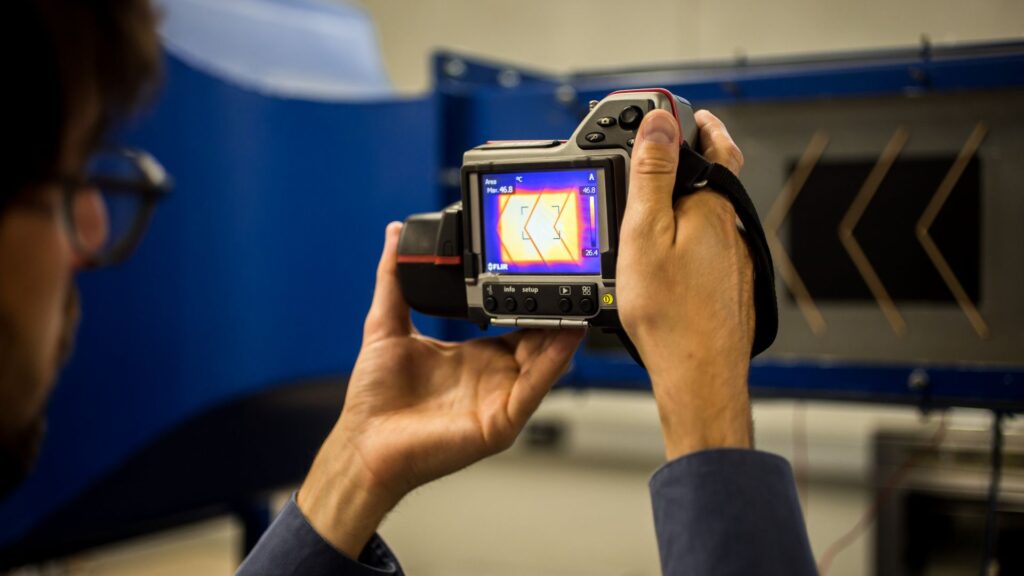

But let’s talk about the lab’s ‘signature’ instruments: the thermal imaging camera…

The thermal imaging camera (or thermographic camera) is a camera sensitive to infrared radiation, which we use to capture thermographic images. Characteristic temperature maps of surfaces are obtained from the detected radiation.

It does not actually measure temperature, but the radiance emitted and reflected by the object. The radiance that is captured by the camera is both that emitted by the object and that which the object reflects. Only the portion emitted by the object itself provides information about the temperature of the object, which is why you have to reduce the reflectance of the object or protect the optical path between the object in the frame and the thermal imaging camera to prevent reflections that could introduce errors in temperature measurements.

Can you explain what reflectance is?

Reflectance is the ability of a surface or material to reflect a portion of the incident radiation. It is the ratio of reflected radiation to incident radiation. In the natural world, there are no materials with a reflectance of 0. In thermal applications, especially when accurate temperature measurements are required using IR thermography, efforts are made to get as close to this value as possible.

The artist Anish Kapoor is famous for having recently used VantaBlack, one of the ‘blackest blacks’, produced by a British company, in his works, which absorbs 99.96% of radiation. VantaBlack is not a naturally occurring black; instead, it is a product of laboratory research.

But what does a thermal image actually tell us?

Reality is not always accurately represented by images, whether in the context of visual culture or in the field of physics.

When we look at a thermal image, what do we see? A temperature. But is it the actual temperature? We need to understand what the equipment actually reads. It may be that certain parts of the object may not be inherently hotter but may reflect the heat emitted by surrounding hot objects, for example. Or that transparent materials usually do not transmit or transmit very little thermal radiation in the visible spectrum and there can be significant noise in the wavelengths ‘seen’ by the thermal camera.

Using infrared technology teaches us which instruments to use to obtain different perspectives and fulfil various objectives. And it teaches us that, in life, there are always multiple points of view when interpreting the world around us, and, dare I say it, the experiences we go through.

And what about these plexi pieces with irregular milling?

They are part of the test specimens used in another line of basic research that began 20 years ago and is now widely used in industry: non-destructive testing using infrared thermography.

Thermography is in fact a non-invasive technique that, thanks to the controlled thermal forcing to the surface of the object, can ‘see’ if there are internal defects. For example, bubbles, delaminations or residues of other materials.

When a surface is exposed to radiation, the energy is absorbed and travels through the material as a thermal wave. As the thermal wave encounters an edge or an irregularity within the material, some of the wave is reflected back to the surface. By measuring the surface temperature using a thermal imaging camera, we would be able to see a warmer spot where the reflected thermal wave reaches the surface again.

Tell us a little about your doctoral thesis

Since my degree thesis on heat transfer on a flat plate, I have been promoted to work on the characterisation of heat transfer in forced convection in ducts with surfaces with different structures. The global measurements allowed us to study and develop heat transfer correlations necessary for other basic research, as well as for the design of heat exchangers with high thermal performance. These exchangers find applications in aeronautics, particularly within turbines for cooling, and in the automotive field. We also used thermographic measurements through these germanium (IR-transparent) windows to obtain local measurements. These local measurements contribute to a deeper understanding of the physics behind thermofluid-dynamic issues within the ducts.

Part of the thesis work involved grouping together all the results to help us find that common thread, mentioned at the start of this interview: the key to finding an optimum where the benefits of increased heat transfer are maximised without causing undesirable consequences in terms of pressure losses.

With a background in aeronautical engineering, I have often wished for sleek surfaces, perhaps with some roughness to reduce fluid dynamic resistance. Here, the goal of increasing heat transfer often forces us to introduce obstacles into the flow of fluid, disrupting the smooth motion and inducing controlled turbulence. In short, there is always a price to pay; and, in the case of the principles of fluid dynamics, part of you must accept these trade-offs and find consolation in the overall objective.

Why are tests like these so important today?

The current problem for companies is the need to create increasingly smaller products with increasingly high performance levels. This requires methods to disperse increasingly large amounts of heat. Until now, this has been a matter of grappling, often oversizing; but now companies are faced with major problems.

Companies approach us with diverse needs, and it is fulfilling to strive to meet each one. These varied requests underscore the significance and beauty of research. It is a fantastic opportunity to open our laboratory to the world.

So can this role be harmonised with that of a ‘basic researcher’?

I would say so, yes. Working with companies means being brought back to more contingent goals and understanding what we can provide to meet the companies’ needs. It is a space at the threshold or frontier of research, which requires us to stick to timeframes. Some areas of basic research have very long lead times which are often associated with a danger of losing focus or becoming entangled in excessive details.

In frontier research making mistakes is essential and you have to let yourself do so. Researchers are a bit like early mountaineers who would go into completely unknown terrain. When trying to find a new route, there is the inherent risk of making miscalculations or not foreseeing certain aspects. Allowing yourself to be wrong and knowing that you can almost always turn back is part of the process. We are here to – responsibly – try our best and strive to achieve our goals.

Tell us how your adventure at Politecnico began

I started off doing aerospace engineering in Lecco, it was a great first year. I finished my three-year degree at Bovisa and then continued with a Master of Science degree in aeronautics, specialising in propulsion, with a thesis on heat transfer. I’ve always liked the topic of heat and where it goes.

I then did my PhD in energy engineering, to stay here as a research fellow. Today I teach, working alongside two professors.

As a specialist, I am not limited to using a specific tool or following a single line of research. In my experience, I see the research project come to life. I follow it through its different phases, including the laboratory work and interactions with counterparts. I am fortunate enough to be fully immersed in all aspects of research, not just the parts that take place in the laboratory.

I noticed the passion with which you talk about yourself and your work…

I’m actually very glad that I have had the opportunity tell my story in this interview: it’s been valuable for me to reflect, look at what I’m doing, how far I’ve come and where I’m going. It’s allowed me to gain perspective, to review my approach to things. Moments of introspection like this are good to catch one’s breath and ask yourself: what am I doing? Where am I going?

Today, I invited you into the complexities of my life, into the intimate aspects of its inherent chaos.

[I look around the laboratory reminiscent of Brâncuși’s studio, I catch a glimpse of several books and handwritten notes that do not seem to be of a scientific nature…]

Have those books been an inspiration to you? Tell me about them?

Those are Ludwig Hohl’s ‘Notes’, which he took for two, three years. The pictures are beautiful. They remind me, albeit with significant respectful differences, of my final year of my PhD where I had notes scattered all over the place before I figured it out.

‘Questo immenso non sapere’ (This immense not-knowing) by Chandra Candiani reminds me that I am not here ‘because they pay me’, but because there is still (and always will be) something I do not know. “This book is messy, and must remain so,” Candiani wrote. Because as I said before, chaos is needed.

The third image that describes me is that of Maria Lai, the mother of community art. In one of her works, a 27-kilometre ribbon that embraces the entire mountain, there is the interweaving with the world thanks to the tools that the group put in our hands. I see in it all the madness, the courage it takes to do frontier research. Like a gift that one gives oneself, that one indulges in. And perhaps, it saves us.

What does working in the laboratory teach you?

Specialists do not have to consciously think about movements because they come to them automatically, they are ingrained in them. If I compare it to mountaineering again, it’s like when you climb a lot and you no longer have to think about the movement. You can enjoy the experience without needing to watch what your hands are doing. The mind just thinks.

In the laboratory, time stands still for a while. In the initial lessons given to students, I insist on a measured approach, and on letting them touch things. Experimenting, learning how to use your hands ‘as a specialist’ is an opportunity for growth. Knowing how to find what you are looking for, how to establish connections with both objects and people outside are valuable lessons learned in the laboratory.

I don’t want to open a gateway to the infinite, but, in brief, what is research for you?

Research also involves researching within oneself. I always feel like I am part of a movement. Sometimes doing things within the movement, and the style in which I do them, is an opportunity for me cultivate a deep appreciation for the world. I also reflect this in my writing: it is an opportunity for synthesis, an opportunity to embrace the world, to engage in dialogue with it, to listen to it.

When you are researching, you sometimes feel like a tightrope walker. You have to balance the fear of not making any progress with the fear of running out of time. And at some point, you have to pull the strings, which happened to me in the last two months of my PhD. Without this deadline, it would have become alienating for me.

But research teaches you, on the other hand, to be patient. This is important because sometimes it takes a while to see the results of your research. Like the old saying says, ‘good things come to those who wait’.