Terms such as ‘clean hydrogen’, ‘decarbonisation’ and ‘circular economy’ are increasingly common when discussing energy and sustainability. But what lies behind these technologies? To understand this, we must start with a fundamental but little-known concept: catalysis.

What is a catalyst? How does it work? And why is it so important in our daily lives — from the environment to health, from energy to industry?

We asked Matteo Maestri, full professor of Chemical Engineering at the Politecnico di Milano and lecturer in the ‘Laboratory of Catalysis and Catalytic Processes — LCCP’ research group in the Department of Energy. In answering these questions, he takes us on a journey through research, technology and future challenges related to this fascinating and crucial field.

Let’s start with the basics. What is catalysis?

A catalyst is a substance that changes the speed of a chemical reaction by facilitating the conversion of reactants into products. It is not consumed and it remains unchanged at the end of the reaction. The catalyst guides the reaction in forming the desired products, favouring specific pathways and limiting the production of unwanted or waste compounds. In the presence of a catalyst, reactions take place under less severe operating conditions, making processes more sustainable and cost-effective.

Can you give us a concrete example of catalysis?

The synthesis of ammonia (NH3) from N2 and H2 is very important because it forms the basis for the production of nitrogen fertilisers and therefore plays a key role in food production for humans. Without a catalyst, this reaction practically does not take place. In the presence of iron-based catalysts, the reaction proceeds at appreciable speeds, making it possible to produce NH3 from the constituent elements, a process that has revolutionised the world.

Besides ammonia, what other examples are there?

Approximately 80–90% of industrial processes include at least one catalytic step. Although we are not fully aware of it, we all have multiple ‘catalytic experiences’ every day, as catalysis plays a crucial role in today’s economy.

Think of everyday gestures: touching objects, driving to work, cleaning the house. For example, every fuel ‘molecule’ has been influenced by at least one catalyst in its production history. We use objects made of materials whose synthesis required several catalytic reactions. Giulio Natta was awarded the Nobel Prize in Chemistry in 1963 for the development of catalysts that affected the stereochemistry of propylene polymerisation to produce isotactic polypropylene, a material that has revolutionised the world.

But catalysis relates not only to industry and economics: natural catalysts, called enzymes, also work in our bodies. These accelerate the biochemical reactions necessary for life without being consumed in the process.

How can catalysis contribute to solving today’s major energy challenges?

Catalysis is a crucial element in the transition to sustainable energy sources. One of the most promising approaches is to ‘store’ energy in chemical bonds. This process occurs due to catalysts that facilitate the combination of molecules such as hydrogen (H₂) and carbon dioxide (CO₂) or hydrogen and nitrogen (N₂), leading to the formation of high-energy compounds such as ammonia (NH₃), methane (CH₄) or other hydrocarbons. Energy is thus ‘trapped’ in chemical bonds and can be released later, for example, through combustion or decomposition.

This all falls under the concept of ‘power to fuel’, or ‘power to X’ in general, in which renewable energy is used to synthesise useful molecules, such as fuels or materials, which can act as energy carriers. It is a way to store energy in a stable, transportable, reusable form.

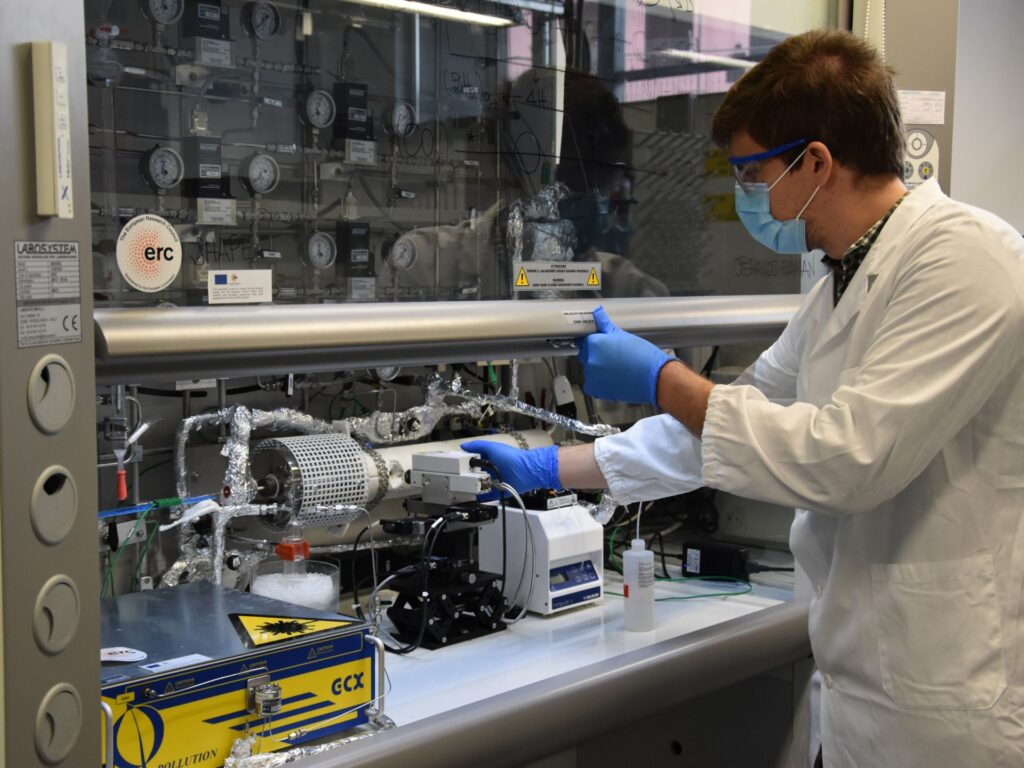

We study several of these catalytic processes in our laboratory. In one of the systems, for example, we analyse the reaction between CO₂ and hydrogen that produces carbon monoxide (CO) and water (H₂O), as a way of transforming CO₂ from a greenhouse gas into a useful resource.

Does catalysis also play a role in the circular economy?

Yes, of course. For example, I mentioned the production of plastics earlier, but it is important to emphasise that catalysis also plays a key role in the opposite process: recycling.

Some advanced catalytic processes break down plastics into simpler compounds, allowing them to be reused. This approach, known as chemical recycling, complements mechanical recycling and can be particularly useful for handling mixed or contaminated plastics that would otherwise end up in landfills or incinerators. This is a fast-growing area with great potential for both reducing environmental impact and recovering valuable resources.

What about reducing pollutants?

One application is the control of nitrogen oxide (NOx) emissions, which are present in engine exhaust and other industrial processes. Catalysis forms the basis of many technologies that reduce these harmful compounds, thus responding directly to environmental challenges. We drive cars that contain systems, such as catalytic converters, that reduce pollutant emissions.

Turning to more personal questions, how did you become interested in these topics?

Even as a child I was fascinated by the way substances transform. I was intrigued to see how a substance could turn into something else. I didn’t know then that it was chemistry, but I was attracted to experiments, the visible transformations.

Perhaps my family background also played a role. In my family, chemical engineering is something of a tradition. My grandfather, father and brother all followed different paths, but always in this field. It was not an explicit influence, but I think it still left a mark.

My real interest in catalysis arose during my Laurea (equivalent to Bachelor of Science) thesis, which was supervised by Professor Tronconi at the Politecnico di Milano. There I started to seriously delve into the subject, and I haven’t stopped since.

Can you tell us about your academic and professional background?

I graduated from the Politecnico di Milano, where I continued my studies with a PhD in chemical engineering and industrial chemistry.

My training began with modelling. In particular, I started by studying the behaviour of chemical reactors and catalysts. Experiences abroad — at the University of Delaware in the USA, the Fritz Haber Institute in Berlin and the Technische Universität München (TUM) in Germany — broadened my skills in the field of kinetics and atomistic modelling, that is, the study of interactions between atoms and molecules. Using these tools, we can now study how a chemical bond is formed or broken, for example, and assess its impact on a given process.

I brought these skills with me when I returned to the Politecnico, first as a researcher and associate professor and then as a full professor starting in 2019. Today, my research team works on these issues. We combine advanced theoretical modelling with experimental work.

Now let’s talk about your research group. What do you do?

My team is part of the Laboratory of Catalysis and Catalytic Processes in the Department of Energy. Founded in the 1970s by Pio Forzatti, today the laboratory has 16 members including professors and researchers and more than 50 students, PhD candidates, postdocs and technicians.

The Laboratory of Catalysis and Catalytic Processes is regarded as an international reference in the study of catalysis and catalytic processes. We take an integrated approach, combining theory and experiments to investigate different aspects of catalysis and catalytic processes.

Since 2008, the group has been part of the Politecnico’s Department of Energy, reflecting the growing role of catalysis in developing technologies in energy and the energy transition.

What is the specific focus of your team in the Laboratory of Catalysis and Catalytic Processes?

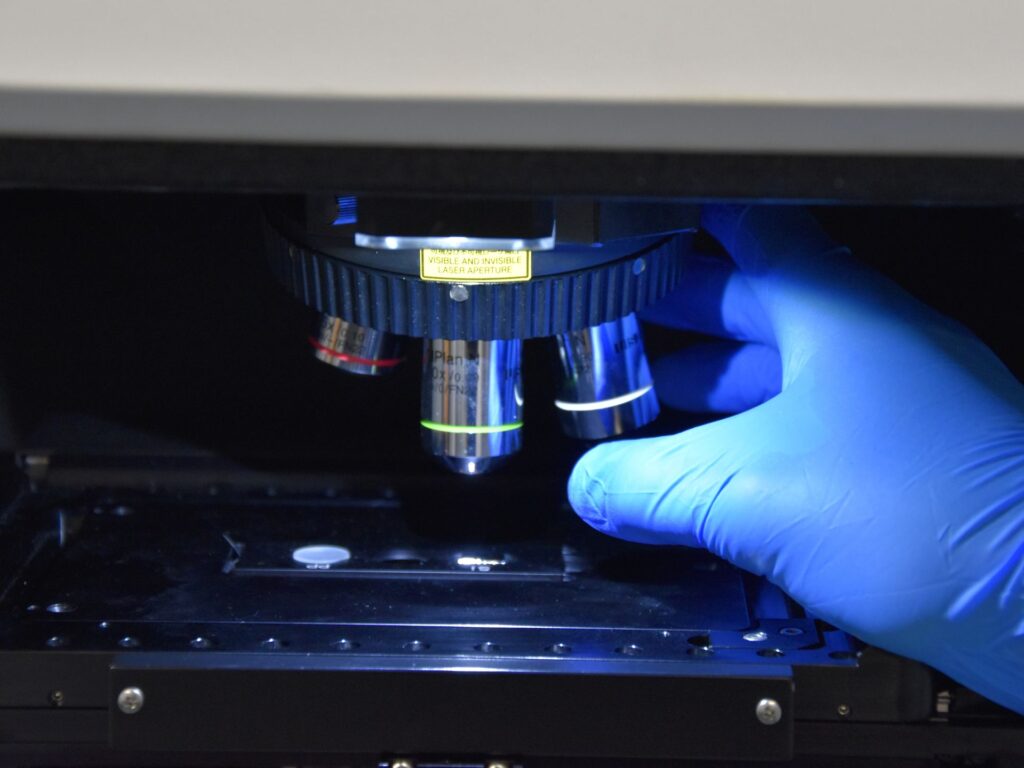

Our team takes a multiscale approach, that is, we study chemical processes by considering several levels simultaneously, from the atomic level to the level of industrial reactors. We try to understand what happens during a chemical reaction, at both the microscopic level — observing how molecules interact with the catalyst surface — and the macroscopic level — analysing the behaviour of the entire reactor. To do so, we combine advanced theoretical models with laboratory experiments, using atomistic simulation and computational fluid dynamics tools together with spectroscopic techniques and kinetic analysis.

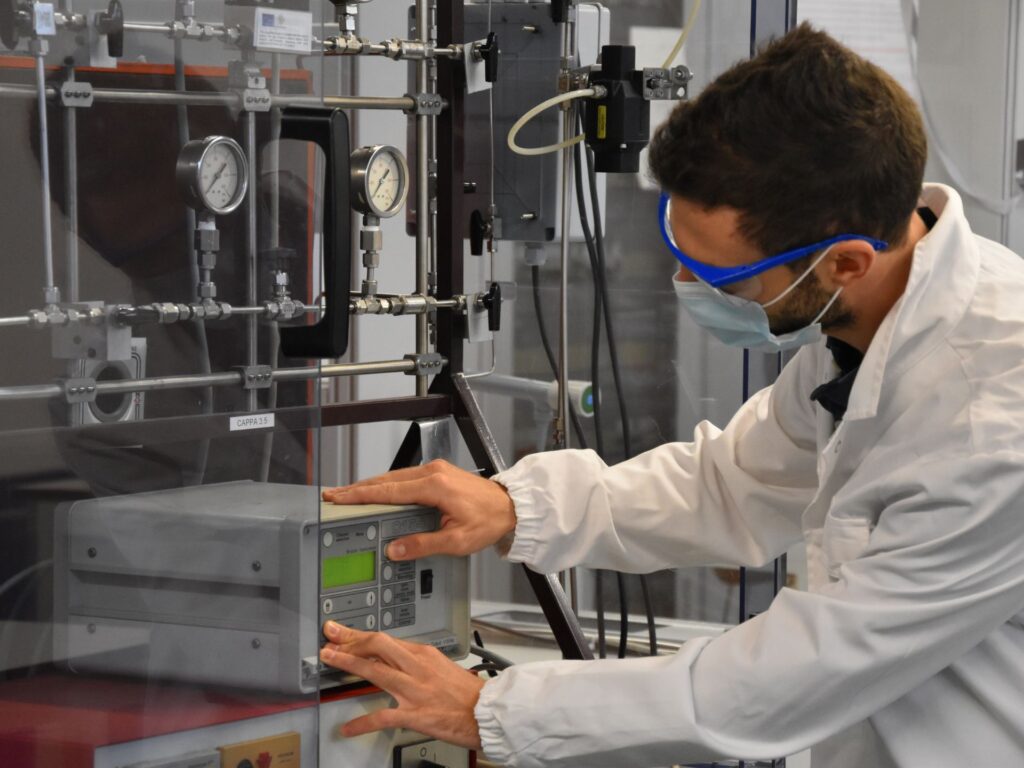

In 2015, we received funding from the European Research Council (ERC) for the SHAPE project, for which we developed state-of-the-art theoretical and experimental methodologies for studying catalytic processes. Using spectroscopy and chemical kinetic techniques, we can observe what happens inside a reactor during reactions in real time and interpret them with advanced modelling methods.

For example, one of the most innovative instruments we have developed is a reactor coupled with spectroscopic techniques, which we use to ‘see’ chemical changes as they occur on the catalyst. This approach allows us to break down the process into all its fundamental parts and then reconstruct a complete, precise view of the system.

Observing reactions in real time is a great innovation. What does it actually mean to ‘see’ what happens on a catalyst?

In a catalytic reaction, one normally measures what goes into the system and what comes out. However, what happens on the surface of the catalyst is often invisible during the reaction. In our work, however, we develop models and tools that allow us to observe exactly these key events. In particular, we have developed experimental ‘online’ spectroscopy techniques, that is, we can follow what happens at the molecular level ‘live’ during the reaction.

In this way, we can validate theoretical models and also obtain new fundamental information. We can say with more certainty that ‘this is how this reaction occurs’. This knowledge provides a map for improving the process. If I want to make it more efficient, what should I change? If I want to use a different, perhaps cheaper or more abundant catalytic material, how should I design the process?

By fully understanding the reaction mechanism, we can drive optimisation and innovation in chemical processes, with concrete benefits for industry and the environment.

What concrete results has your research produced?

Our research starts with fundamental aspects, but it always has very concrete results for applications. For instance, it led to two ERC Proof of Concepts, initiatives designed to transform research results into marketable solutions.

The first concerns the development of an experimental reactor, while the second is a modelling program designed to simulate and optimise catalytic processes.

The latter led to a spin-off of the Politecnico di Milano, which will be responsible for its commercialisation. If all goes according to plan, we expect to market the first licences as early as September.

What changes are there when research also becomes a product?

In our case, we noticed that some tools developed in academia — particularly our software — were beginning to attract the interest of industry. These were no longer just collaborations, but actual requests from companies to use the tools.

Hence the idea of the spin-off, which also had the support of the ERC PoC Catalyse project. In this case, we focused on technologically modifying the research we had developed in our laboratories. We worked on the interface to make the software more intuitive, adapting it to the needs of those working in the chemical and energy sectors.

We also thought about its use in education. The software can be used in university courses or vocational training so that students already learn to master advanced tools during their studies.

What are the next steps in the field of catalysis?

The field of catalysis is evolving quickly, driven by urgent global needs such as decarbonisation, the sustainability of industrial processes and resource optimisation. The next objectives lie on several levels regarding applications and methodology.

With respect to applications, one of the main challenges is to design catalysts that can operate under more stringent conditions, with greater selectivity for the desired product and a longer operating life. This is crucial for reducing energy consumption in industrial processes and minimising the formation of unwanted by-products.

In addition, there is a growing focus on the use of abundant, nontoxic and recyclable materials to replace rare and expensive metals with more sustainable alternatives.

The ability to integrate renewable energy into chemical reactions and processes, whether through electrocatalysis or electrified reactors, is also becoming a key aspect. With respect to methodology, catalysis is undergoing a profound transformation due to its increasing integration with advanced artificial intelligence and machine learning tools.

These technologies make it possible to address the complexity of catalytic systems more systematically and efficiently, enabling accelerated exploration of the chemical aspects of materials and more accurate prediction of their catalytic properties. To fully exploit this potential, it will be crucial to synergistically integrate advanced theoretical modelling with advanced experimental techniques. By combining reliable laboratory data with physical models and robust predictive algorithms, it will be possible to gain a deep understanding of catalytic mechanisms and effectively guide the development of innovative materials and processes.

And with respect to your own personal research?

In addition to continuing work on the processes we are currently studying, my own research also focuses on an aspect that I consider crucial and underexplored: the catalyst life cycle, with particular attention to deactivation mechanisms. Understanding why and how a catalyst loses its activity over time is a complex scientific challenge involving chemical, structural and environmental phenomena on different and often interconnected scales.

The aim is not only to diagnose degradation, but also anticipate it and, ideally, prevent it through smarter design strategies. If we could make a catalyst last even one year longer, the industrial benefits would be significant, both economically and environmentally: less waste of critical materials, lower replacement frequency and greater overall process efficiency.

To address this challenge, I am working to integrate advanced experimental approaches, such as spectroscopy, with computational models to help reconstruct and predict the evolution of the catalytic system over time. I believe that studying the catalyst life cycle is a fundamental and impactful step.

What is the average lifetime of a catalyst?

It depends very much on the process. There are catalysts that last a fraction of a second, but are continuously regenerated. Others, however, remain active for years.

Understanding how to keep them ‘alive’ longer is a challenge on several levels — scientifically, technically and industrially. It is a perfect example of how research can bring tangible benefits, both economic and environmental.

Any final thoughts?

Yes. There is one aspect that I consider particularly important: the training impact of research. Beyond the scientific or technological results, every university project also contributes to the growth of the people involved. In many cases, training students and researchers in research projects resembles work in an atelier. They learn in the field alongside experienced researchers, developing solid skills and a critical approach to problems.

When they enter the industrial world, they not only transfer what they have learnt, but also often become true enablers of innovation. In this sense, students trained through research projects are themselves a way to transfer technology, skills and experience, perhaps less visible than a spin-off, but just as effective and more immediate in generating value.

Some of my former students have concretely demonstrated the importance of the training they received, taking with them their skills and added value when they enter industry. Others have stayed in academia and are now my colleagues. One of them, for example, started as a thesis student in one of our projects and is now an associate professor and a close collaborator in various research activities.

Following these career paths over time is a source of great satisfaction. After all, one of the most significant aspects of this profession is contributing to the growth of new generations of researchers and professionals.