The textile industry is one of the dominant sectors of the world economy, and consequently one of the most controversial. In a planet undergoing profound transformation, the role of digital technologies is fundamental to addressing the challenges of the future, first and foremost that of sustainability.

We talked about that with Rabia Hassan, PhD candidate at the Department of Management, Economics and Industrial Engineering of the Politecnico di Milano.

Hi Rabia. What characterizes the textile sector right now?

Currently, the textile sector is characterized by two simultaneous transformations: a shift towards circularity and an increasing emphasis on digitalization. At the same time, there is mounting pressure from consumers, policymakers, and environmental groups for the industry to adopt more sustainable practices.

We are witnessing a technological revolution marked by innovations such as blockchain, artificial intelligence, and 3D technologies. However, literature reveals a significant gap in the integration of these two transformations, with very few studies addressing the intersection of circular economy principles and digitalization.

This is when your research kicks in. What is the main focus?

Our primary aim was to bridge this gap and provide guidance to the textile sector to facilitate its transition towards circularity. In collaboration with my co-authors, Federica Acerbi, Paolo Rosa, and Sergio Terzi, we focused on leveraging digital technologies to help the textile industry shift from the traditional linear economy—characterized by a take-make-waste approach—towards a more circular model.

The textile industry is a major consumer of resources and has a significant environmental impact, ranking fourth after food, housing, and mobility in terms of resource usage. This highlights the urgent need for optimization processes that enhance transparency and reduce waste within the industry.

To address this need, we developed a framework of digital technologies aimed at supporting the textile industry in enhancing its circularity. By integrating these technologies, we believe the sector can make substantial strides towards more sustainable practices.

In your opinion, what was the cause of the lack of studies in digitalization within the textile sector?

In my view, it can be attributed to several interrelated factors. One significant reason is the scarcity of comprehensive data linking digital technology to circular economy practices in the industry.

Textile companies encounter both technical and organizational challenges when attempting to integrate these technologies to support sustainable practices.

A primary barrier is the substantial cost associated with implementing digital technologies, such as blockchain and artificial intelligence. To successfully invest in these technologies, companies must consider not only the hardware and software required but also the necessary employee training to ensure effective management and implementation.

Furthermore, many textile companies struggle with a lack of expertise. There is often insufficient technical knowledge within organizations, which makes it difficult to implement and manage these advanced systems.

Additionally, concerns about data security loom large; as digital systems become increasingly integrated into business operations, the risk of cyber-attacks escalates.

Are these barriers specifically linked to costs or is it also a matter of workflow and process?

Many companies lack specific strategies for implementing digital technologies, which can lead to confusion and hinder progress among employees and managers.

It’s important to recognize that many textile industries have deep-rooted traditional production methods. There can be significant hesitance to adopt new systems, driven by a mindset resistant to change. This combination of challenges ultimately inhibits their potential to achieve circular practices.

How can companies overcome the barriers to enhancing circularity within the textile sector?

Strategic partnerships with technology providers can play a crucial role in overcoming these challenges. Collaborating with technology experts can help reduce the substantial costs associated with implementing digital technologies, enabling a step-by-step investment approach. Government support is equally vital. Providing funding, grants, and policy initiatives can help accelerate the adoption of circular practices.

Equally important is the development of knowledge among the workforce. Companies must prioritize educating their employees on digital technologies, as their understanding is critical to successfully implementing circularity within the organization. Once employees are equipped with the necessary skills, the next step is to educate consumers. If the workforce lacks the capability to embrace and apply these technologies, the broader goal of circularity will be difficult to achieve.

Leaders must also actively promote a culture of innovation. This can be achieved by organizing workshops, seminars, and other initiatives that encourage both staff and consumers to engage with new systems and continuously improve processes. Involving consumers in the circularity process is crucial, as they play a central role in the success of these initiatives. Brands should strive to raise awareness among their customers about how they can incorporate circular practices into their daily lives, whether through reusing, repairing, or renting products.

Is it feasible for major brands to implement such policies? Are they genuinely committed to circularity, or are they merely engaging in greenwashing?

Yes, it is indeed possible for these brands to adopt such policies, and we are already seeing examples of this in practice. For instance, a well-known clothing brand has implemented blockchain technology to track the lifecycle of its products.

This technology not only provides transparency but also offers consumers proof that the materials used in their products are recyclable. Additionally, consumers are encouraged to return garments they no longer use, ensuring that these items are properly recycled. This initiative builds consumer trust and enhances the credibility of the brand’s commitment to circularity.

Are there some other examples?

Another example is a sportswear brand, which has adopted in-store 3D printing technology to create custom-fit products for customers, offering personalization in design and material choices within hours.

These examples show that the implementation of circular practices can indeed make a difference. By demonstrating transparency and actively promoting sustainability, brands can foster greater consumer trust and drive the adoption of circularity within the industry.

In the context of Italian textile brands, where do we stand in terms of sustainability?

Although my research did not specifically focus on the Italian textile sector, I recently had a conversation with an Italian expert on this topic. I was surprised to learn that there is still much work to be done in Italy regarding sustainability in textiles. However, there are also Italian companies that are eager to implement digital technologies and circular practices, showing a positive shift towards sustainable solutions.

At present, the Italian industry seems to be at a crossroads. While progress is being made, companies face significant challenges in fully adopting digital technologies. I believe that in the next five to ten years, digital technologies will become essential for the successful implementation of circularity. It is crucial for governments to introduce enforceable regulations that mandate the integration of these technologies within the sector. The connection between digital innovation and circularity cannot be overstated, and it is vital for the future of the textile industry.

Is your interest in circular economy and sustainability influenced by the fact that the textile industry in Pakistan is the largest manufacturing sector?

Yes, absolutely. Pakistan has one of the largest textile industries in the world, producing a vast array of textile products. However, when comparing the implementation of circular economy strategies between European Union countries and Pakistan, there is a noticeable gap.

While some countries have made significant strides, Pakistan still faces challenges in adopting such strategies on a large scale. This is due, in part, to the lack of infrastructure and governmental support needed to effectively implement circular economy principles.

What is the main difference between the mindsets in Pakistan and Italy regarding sustainability?

There is a significant difference in mindset when it comes to resource use and sustainability.

For example, I can share a personal anecdote. In my own wardrobe, I don’t accumulate excess clothing. I buy only what I need, and I use clothes until they can no longer serve their purpose. In Pakistan, people tend to make the most of what they have, reusing items for different purposes—such as turning old clothes into cleaning rags—rather than discarding them immediately. However, despite this frugality, there is a lack of proper waste management strategies and systems to optimize circularity.

In contrast, Italy has a more structured approach to sustainability, largely due to stronger government support and better-established infrastructure for recycling and circularity. While there is still much to be done, the gap in resources and systems is less pronounced compared to Pakistan.

In the future, which technologies could facilitate the implementation of a circular economy mindset in the textile industry?

Looking ahead, one of the most promising technologies for fostering circularity is the widespread adoption of digital product passports.

These passports would capture and communicate critical information about a product throughout its lifecycle, helping stakeholders—consumers, manufacturers, recyclers, and brands—understand key data and make informed decisions about the product’s reuse, recycling, or disposal.

What is a digital product passport?

A digital product passport is essentially a unique identification system for each product. It would provide detailed information about the materials used in its creation—such as whether the fabric is made from organic cotton, recycled polyester, or wool—along with information about the dyes and chemicals used.

For example, a consumer could scan a product’s digital passport to learn about the origin of the cotton used in their garment or the type of chemicals involved in its production.

This technology is particularly valuable in recycling, where knowing the composition of materials—such as the chemicals used—can help determine the most efficient recycling process, whether mechanical or chemical.

Digital product passports will significantly enhance product life cycle management and resource optimization, leading to reduced waste and increased sustainability in the textile industry.

One of the outcomes of your research is a framework for companies in the textile sector. How can we easily read it?

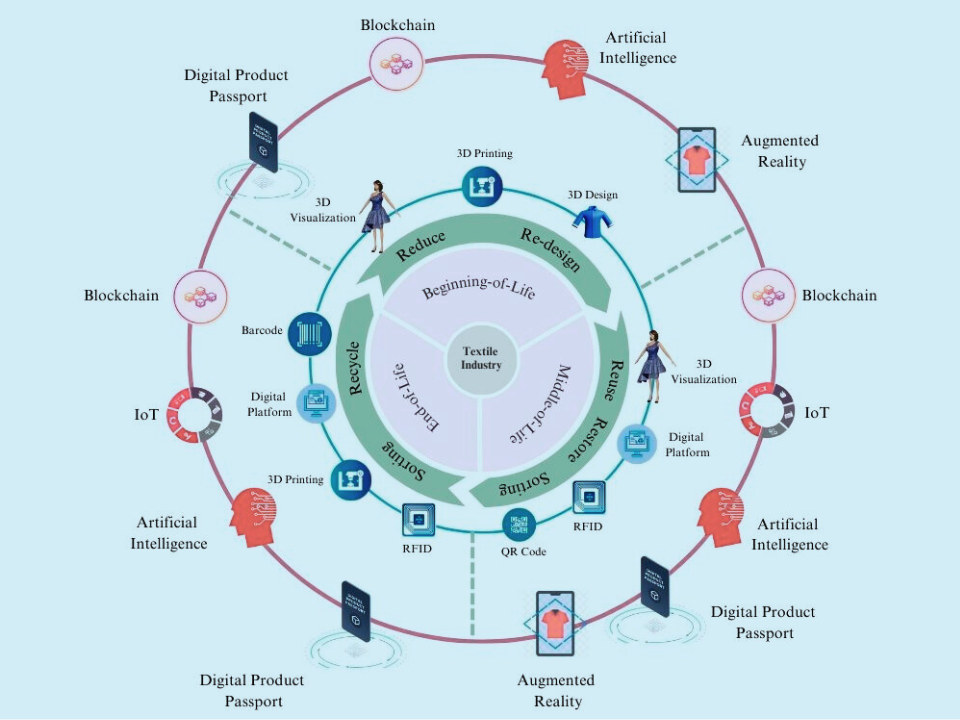

The framework scheme is divided into two sections, represented by two colours. The blue section represents current technologies, while the red section highlights advanced technologies with future potential. This distinction is important because it allows companies to understand where they currently stand in terms of technology implementation and where they could move in the future.

At the beginning-of-life stage, technologies like 3D visualization, 3D printing, and 3D design assist in sample creation and redesign, minimizing water and chemical consumption. 3D visualization, in particular, helps buyers assess clothing before making a purchase, reducing the demand for new products.

In the middle-of-life phase, technologies like 3D visualization and digital platforms help promote second-hand clothing. They enable consumers to visualize second-hand items online, making it easier to evaluate their condition and suitability. Digital platforms also help connect sellers of pre-loved clothing with potential buyers, while technologies like QR codes and RFID tags improve the sorting and tracking of garments based on their condition and usability. These technologies enhance transparency and traceability throughout the supply chain, which is critical for fostering trust in second-hand markets.

At the end-of-life stage, 3D printing can be used to recycle old garments into new products, providing a sustainable alternative to disposal. Digital platforms play a key role in raising awareness about the importance of recycling, engaging consumers and businesses in sustainable waste management practices.

Why is blockchain so crucial in revolutionizing practices in the textile industry?

By enabling secure, transparent tracking of garments throughout their entire life cycle, blockchain enhances product verification, supply chain transparency, and the management of recycled materials.

Blockchain could facilitate the secure exchange of data between stakeholders, improving recycling efficiency and helping companies optimize resource use.

Do you believe this framework will be successful in guiding companies toward circularity?

I believe it will be highly valuable for textile companies that are ready to integrate digital technologies into their operations. It serves as a guide to help companies and academia identify the technologies essential for transitioning to a circular economy.

We would like to get to know you a little better. Could you share with us a bit about your academic and professional journey?

My academic journey began in Pakistan, where I was born and raised. I obtained my bachelor’s degree in 2013, after which I began my professional career in the automotive industry, specifically in the product development department. Over the next five years, from 2014 to 2019, I gained extensive experience and honed my management skills, all while balancing my professional duties with further studies.

During this time, I pursued a Master’s degree in Management Engineering, which I successfully completed in 2017. Juggling work and studies was challenging, but I managed to balance both and further solidify my expertise in management.

In 2020, I made a significant shift towards academia, joining a teaching position that marked a turning point in my career. This transition into academia sparked a strong passion for scientific research, which ultimately influenced my decision to continue my academic journey.

In 2023, I enrolled in the PhD program at Politecnico di Milano to further deepen my knowledge and contribute to research in the fields of sustainability and circular economy.

How did you start to study the topic of circularity within the textile sector?

I was fortunate to secure funding from PNRR in Italy on the topic of sustainability to improve circularity for Made in Italy. So, under the supervision of Professor Sergio Terzi, I continued my research for three years at the Department of Management, Economics and Industrial Engineering.

Over the past two years, I collaborated with the experts on the textile industry that is the most suitable sector for conducting this kind of studies at its faces.

What are your plans for the near future?

I’m attending my third year of PhD, so I aim to finish PhD with focusing on my research and, at the same time, I have to plan next steps in academic path. After completing my PhD I am considering continuing my work at Politecnico di Milano, possibly through a postdoc or a research position, but I still have to explore my options.

Hi Rabia. What characterizes the textile sector right now?

Currently, the textile sector is characterized by two simultaneous transformations: a shift towards circularity and an increasing emphasis on digitalization. At the same time, there is mounting pressure from consumers, policymakers, and environmental groups for the industry to adopt more sustainable practices.

We are witnessing a technological revolution marked by innovations such as blockchain, artificial intelligence, and 3D technologies. However, literature reveals a significant gap in the integration of these two transformations, with very few studies addressing the intersection of circular economy principles and digitalization.

This is when your research kicks in. What is the main focus?

Our primary aim was to bridge this gap and provide guidance to the textile sector to facilitate its transition towards circularity. In collaboration with my co-authors, Federica Acerbi, Paolo Rosa, and Sergio Terzi, we focused on leveraging digital technologies to help the textile industry shift from the traditional linear economy—characterized by a take-make-waste approach—towards a more circular model.

The textile industry is a major consumer of resources and has a significant environmental impact, ranking fourth after food, housing, and mobility in terms of resource usage. This highlights the urgent need for optimization processes that enhance transparency and reduce waste within the industry.

To address this need, we developed a framework of digital technologies aimed at supporting the textile industry in enhancing its circularity. By integrating these technologies, we believe the sector can make substantial strides towards more sustainable practices.

In your opinion, what was the cause of the lack of studies in digitalization within the textile sector?

In my view, it can be attributed to several interrelated factors. One significant reason is the scarcity of comprehensive data linking digital technology to circular economy practices in the industry.

Textile companies encounter both technical and organizational challenges when attempting to integrate these technologies to support sustainable practices.

A primary barrier is the substantial cost associated with implementing digital technologies, such as blockchain and artificial intelligence. To successfully invest in these technologies, companies must consider not only the hardware and software required but also the necessary employee training to ensure effective management and implementation.

Furthermore, many textile companies struggle with a lack of expertise. There is often insufficient technical knowledge within organizations, which makes it difficult to implement and manage these advanced systems.

Additionally, concerns about data security loom large; as digital systems become increasingly integrated into business operations, the risk of cyber-attacks escalates.

Are these barriers specifically linked to costs or is it also a matter of workflow and process?

Many companies lack specific strategies for implementing digital technologies, which can lead to confusion and hinder progress among employees and managers.

It’s important to recognize that many textile industries have deep-rooted traditional production methods. There can be significant hesitance to adopt new systems, driven by a mindset resistant to change. This combination of challenges ultimately inhibits their potential to achieve circular practices.

How can companies overcome the barriers to enhancing circularity within the textile sector?

Strategic partnerships with technology providers can play a crucial role in overcoming these challenges. Collaborating with technology experts can help reduce the substantial costs associated with implementing digital technologies, enabling a step-by-step investment approach. Government support is equally vital. Providing funding, grants, and policy initiatives can help accelerate the adoption of circular practices.

Equally important is the development of knowledge among the workforce. Companies must prioritize educating their employees on digital technologies, as their understanding is critical to successfully implementing circularity within the organization. Once employees are equipped with the necessary skills, the next step is to educate consumers. If the workforce lacks the capability to embrace and apply these technologies, the broader goal of circularity will be difficult to achieve.

Leaders must also actively promote a culture of innovation. This can be achieved by organizing workshops, seminars, and other initiatives that encourage both staff and consumers to engage with new systems and continuously improve processes. Involving consumers in the circularity process is crucial, as they play a central role in the success of these initiatives. Brands should strive to raise awareness among their customers about how they can incorporate circular practices into their daily lives, whether through reusing, repairing, or renting products.

Is it feasible for major brands to implement such policies? Are they genuinely committed to circularity, or are they merely engaging in greenwashing?

Yes, it is indeed possible for these brands to adopt such policies, and we are already seeing examples of this in practice. For instance, a well-known clothing brand has implemented blockchain technology to track the lifecycle of its products.

This technology not only provides transparency but also offers consumers proof that the materials used in their products are recyclable. Additionally, consumers are encouraged to return garments they no longer use, ensuring that these items are properly recycled. This initiative builds consumer trust and enhances the credibility of the brand’s commitment to circularity.

Are there some other examples?

Another example is a sportswear brand, which has adopted in-store 3D printing technology to create custom-fit products for customers, offering personalization in design and material choices within hours.

These examples show that the implementation of circular practices can indeed make a difference. By demonstrating transparency and actively promoting sustainability, brands can foster greater consumer trust and drive the adoption of circularity within the industry.

In the context of Italian textile brands, where do we stand in terms of sustainability?

Although my research did not specifically focus on the Italian textile sector, I recently had a conversation with an Italian expert on this topic. I was surprised to learn that there is still much work to be done in Italy regarding sustainability in textiles. However, there are also Italian companies that are eager to implement digital technologies and circular practices, showing a positive shift towards sustainable solutions.

At present, the Italian industry seems to be at a crossroads. While progress is being made, companies face significant challenges in fully adopting digital technologies. I believe that in the next five to ten years, digital technologies will become essential for the successful implementation of circularity. It is crucial for governments to introduce enforceable regulations that mandate the integration of these technologies within the sector. The connection between digital innovation and circularity cannot be overstated, and it is vital for the future of the textile industry.

Is your interest in circular economy and sustainability influenced by the fact that the textile industry in Pakistan is the largest manufacturing sector?

Yes, absolutely. Pakistan has one of the largest textile industries in the world, producing a vast array of textile products. However, when comparing the implementation of circular economy strategies between European Union countries and Pakistan, there is a noticeable gap.

While some countries have made significant strides, Pakistan still faces challenges in adopting such strategies on a large scale. This is due, in part, to the lack of infrastructure and governmental support needed to effectively implement circular economy principles.

What is the main difference between the mindsets in Pakistan and Italy regarding sustainability?

There is a significant difference in mindset when it comes to resource use and sustainability.

For example, I can share a personal anecdote. In my own wardrobe, I don’t accumulate excess clothing. I buy only what I need, and I use clothes until they can no longer serve their purpose. In Pakistan, people tend to make the most of what they have, reusing items for different purposes—such as turning old clothes into cleaning rags—rather than discarding them immediately. However, despite this frugality, there is a lack of proper waste management strategies and systems to optimize circularity.

In contrast, Italy has a more structured approach to sustainability, largely due to stronger government support and better-established infrastructure for recycling and circularity. While there is still much to be done, the gap in resources and systems is less pronounced compared to Pakistan.

In the future, which technologies could facilitate the implementation of a circular economy mindset in the textile industry?

Looking ahead, one of the most promising technologies for fostering circularity is the widespread adoption of digital product passports.

These passports would capture and communicate critical information about a product throughout its lifecycle, helping stakeholders—consumers, manufacturers, recyclers, and brands—understand key data and make informed decisions about the product’s reuse, recycling, or disposal.

What is a digital product passport?

A digital product passport is essentially a unique identification system for each product. It would provide detailed information about the materials used in its creation—such as whether the fabric is made from organic cotton, recycled polyester, or wool—along with information about the dyes and chemicals used.

For example, a consumer could scan a product’s digital passport to learn about the origin of the cotton used in their garment or the type of chemicals involved in its production.

This technology is particularly valuable in recycling, where knowing the composition of materials—such as the chemicals used—can help determine the most efficient recycling process, whether mechanical or chemical.

Digital product passports will significantly enhance product life cycle management and resource optimization, leading to reduced waste and increased sustainability in the textile industry.

One of the outcomes of your research is a framework for companies in the textile sector. How can we easily read it?

The framework scheme is divided into two sections, represented by two colours. The blue section represents current technologies, while the red section highlights advanced technologies with future potential. This distinction is important because it allows companies to understand where they currently stand in terms of technology implementation and where they could move in the future.

At the beginning-of-life stage, technologies like 3D visualization, 3D printing, and 3D design assist in sample creation and redesign, minimizing water and chemical consumption. 3D visualization, in particular, helps buyers assess clothing before making a purchase, reducing the demand for new products.

In the middle-of-life phase, technologies like 3D visualization and digital platforms help promote second-hand clothing. They enable consumers to visualize second-hand items online, making it easier to evaluate their condition and suitability. Digital platforms also help connect sellers of pre-loved clothing with potential buyers, while technologies like QR codes and RFID tags improve the sorting and tracking of garments based on their condition and usability. These technologies enhance transparency and traceability throughout the supply chain, which is critical for fostering trust in second-hand markets.

At the end-of-life stage, 3D printing can be used to recycle old garments into new products, providing a sustainable alternative to disposal. Digital platforms play a key role in raising awareness about the importance of recycling, engaging consumers and businesses in sustainable waste management practices.

Why is blockchain so crucial in revolutionizing practices in the textile industry?

By enabling secure, transparent tracking of garments throughout their entire life cycle, blockchain enhances product verification, supply chain transparency, and the management of recycled materials.

Blockchain could facilitate the secure exchange of data between stakeholders, improving recycling efficiency and helping companies optimize resource use.

Do you believe this framework will be successful in guiding companies toward circularity?

I believe it will be highly valuable for textile companies that are ready to integrate digital technologies into their operations. It serves as a guide to help companies and academia identify the technologies essential for transitioning to a circular economy.

We would like to get to know you a little better. Could you share with us a bit about your academic and professional journey?

My academic journey began in Pakistan, where I was born and raised. I obtained my bachelor’s degree in 2013, after which I began my professional career in the automotive industry, specifically in the product development department. Over the next five years, from 2014 to 2019, I gained extensive experience and honed my management skills, all while balancing my professional duties with further studies.

During this time, I pursued a Master’s degree in Management Engineering, which I successfully completed in 2017. Juggling work and studies was challenging, but I managed to balance both and further solidify my expertise in management.

In 2020, I made a significant shift towards academia, joining a teaching position that marked a turning point in my career. This transition into academia sparked a strong passion for scientific research, which ultimately influenced my decision to continue my academic journey.

In 2023, I enrolled in the PhD program at Politecnico di Milano to further deepen my knowledge and contribute to research in the fields of sustainability and circular economy.

How did you start to study the topic of circularity within the textile sector?

I was fortunate to secure funding from PNRR in Italy on the topic of sustainability to improve circularity for Made in Italy. So, under the supervision of Professor Sergio Terzi, I continued my research for three years at the Department of Management, Economics and Industrial Engineering.

Over the past two years, I collaborated with the experts on the textile industry that is the most suitable sector for conducting this kind of studies at its faces.

What are your plans for the near future?

I’m attending my third year of PhD, so I aim to finish PhD with focusing on my research and, at the same time, I have to plan next steps in academic path. After completing my PhD I am considering continuing my work at Politecnico di Milano, possibly through a postdoc or a research position, but I still have to explore my options.

Surely, at the moment, my main focus are my outcomes, especially finalizing thesis on circular economy sustainability, my main field of interest.