The new Anechoic Wind Tunnel is a unique academic facility throughout Italy. It was inaugurated at the Bovisa campus during the International Engineering Festival 2025, in September. It’s a new tool available to university researchers, and private companies, to carry out aeroacoustic measurement tests. It joins the existing wind tunnels of the DAER – Department of Aerospace Science and Technology’s Aerodynamics Laboratory, and the Wind Tunnel of the Politecnico di Milano, the largest in Europe, to provide highly advanced services with a specific purpose. Indeed, the plant was funded through MOST – National Centre for Sustainable Mobility, particularly within the Spoke 1 Air Mobility plan, to promote studies on sustainable urban air mobility.

Alex Zanotti, professor of Fluid Dynamics at the DAER, and Donato Grassi, in charge of the Aerodynamics Laboratory, will tell us about it.

There are already anechoic chambers at the Cremona Campus, and at the Department of Energy of the Politecnico di Milano. Moreover, there are already wind tunnels on the Bovisa campus. Why was it deemed necessary to build a new infrastructure that combined the two?

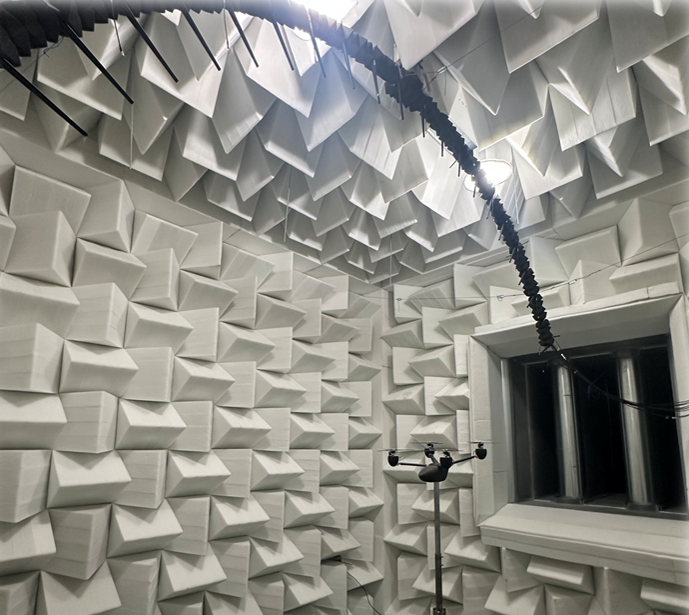

Alex Zanotti: We were involved in MOST’s Spoke 1 for aspects concerning aeronautics and aviation. We proposed the construction of this plant because there are very few such facilities in Europe, and those are typically developed by companies, especially in the automotive sector. However, in our case the need arises from one of the objectives of Spoke 1 of the National Centre MOST, namely the study of problems related to electric vertical takeoff aircraft, eVTOLs, for ultimate sustainable urban air mobility. The need stems from the fact that acoustic measurements can be made on “still” models in an anechoic chamber, as the relative wind condition typical of flight is not considered. Of course, I can reproduce such conditions in a classical Wind Tunnel, but the acoustic measurements would be unreliable as they would be influenced by the noise produced by the system itself, for example by the presence of the test chamber walls, or by the engines used to move the air flow in the duct. Hence, we built a new one, because adapting an existing Wind Tunnel to perform acoustic measurements is complicated. The type of design required for a system suitable for aeroacoustic measurements is completely different. We started from a blank sheet, about three years ago, designing the plant ourselves. Then we hired an external company to build the ducts and the anechoic test chamber.

In terms of project planning, what were the challenges, the differences to be considered regarding design and materials? What are the technical features of the plant?

Z: The acoustic impact produced by air flow inside the tunnel duct has to be reduced or limited as much as possible; therefore, first of all the walls of the ducts are lined with soundproofing material. In addition, the ducts present sectors that act as “silencers”, besides the choice of a specifically selected “low acoustic impact” cooler. Another design problem is that the walls of the test chamber of a “classical” Wind Tunnel produce reflections of sound waves near the model to be tested. This obviously has a negative effect on the quality of the acoustic measurement; therefore, anechoic wind tunnels are generally made to generate a free jet within an anechoic chamber of greater volume. Furthermore, a jet manifold with a much larger cross-section is made to reduce the spurious acoustic effects related to the ingestion of the jet in the return duct. It follows that, also concerning layout, the test chamber in this case is very different from that of a normal Wind Tunnel.

Donato Grassi: The size of our anechoic tunnel was based on the space available in our laboratory. We have a jet section of 70 cm by 50 cm, and the air jet speed can reach 43 metres per second with a turbulence intensity at the exit of the section below 0.2%. These parameters were our project target as our tests generally work around a speed of 30 metres per second, about 100 km per hour, which is the cruising speed of this type of flying machines in an urban environment. We have also just completed the acoustic qualification of the plant by finding background noise values in the test chamber in line with the main academic anechoic tunnels in the world.

What is tested inside the Anechoic Wind Tunnel?

Z: We want to test scale models of propellers, rotors or complete vertical take-off machines, starting from a propeller model of an eVTOL on a 1:5 scale, to finally create a full scale 1:16 eVTOL aircraft, such as the four-rotor drone for the transport of people developed by us at MOST. Of course it will be possible to test other things, from a motorcycle helmet to a model of an airplane wing. But the primary goal for which the plant was designed, as I said, is sustainable urban air mobility. It is a research asset of both our Department and our Aeroacoustics research team.

What does “sustainable urban mobility” precisely mean?

Z: As already mentioned, we are talking about research on new electric vertical take-off machines. These aircrafts are designed to relieve traffic congestion in large conurbations by allowing, for example, air links between hubs built in either city centres or airports.

The issue of “noise” is essential, since people who live near airports, especially those situated near urban centres, already complain… Is this the specific aspect being tested here?

Z: That’s right. Let’s imagine that these machines should be able to fly even over city centres, in an urban environment. In addition to aircraft performance, we need to quantify and improve the acoustic impact of such solutions, which involve the use of numerous rotors. If a helicopter rotor already produces a very high noise level, we can well imagine the acoustic impact of several rotors that also interact with each other. Our plant will obviously also record purely fluid dynamic measurements, but we can reproduce an anechoic environmental condition with a moving flow, in order to measure the effect of the acoustic signature produced by models that reproduce these aircraft architectures.

How important is such a facility for research?

Z: The advantage is to have a state-of-the-art instrument for experimental investigation available in the same research team, in addition to previous numerical modelling capabilities. This leads us to be a centre of excellence for the study of aeroacoustics. Such capabilities are also rare at European level. Only high-level academic institutions, such as TU Delft, or leading aerospace research centres such as ONERA, DLR or NASA have similar capabilities.

Will the Anechoic Wind Tunnel at MOST also serve other universities and their researchers?

Z: There have already been expressions of interest. We expect more after a public presentation of the plant’s technical features at the world’s largest aeroacoustics conference held in Brussels in May. We have a series of test cases already appraised in the classic Wind Tunnel for aerodynamic performance. We want to test them in the anechoic tunnel, including the quadrotor model developed at MOST.

This will also help companies in the sector.

Z: We already work with several companies developing eVTOL, and we run tests in our Wind Tunnel. We provide the know-how of the Politecnico to develop these aircraft for sustainable mobility. We also develop numerical solvers suitable for the simulation of such complex machines. The new anechoic tunnel will be a further tool to investigate noise, an essential aspect for social acceptance, without which these machines will never fly, despite being technically effective.

Established routes should also be followed to fly over cities, including for security reasons.

Z: These aircrafts, which could be ready in the coming years, will be initially tested following established routes, defined by the airlines together with aviation regulators and control bodies. Plans are being made, for example, for routes in the United States and in the United Arab Emirates to connect major airport hubs with cities. Hopefully, as technology advances, it will become a service that can be accessed by the whole community. To this end, it will be important to achieve a certain degree of social acceptability regarding the flight of such machines. We need to define the costs for the most interesting journeys and routes… The first prototypes are already flying; however, they need to obtain airworthiness certification before we can see them fly over our skies.

How close is such a solution in the near future? Are there already any tests in progress on such vehicles?

Z: As I said, there are companies that are already trying to certify their aircraft in the United States. We are talking about the first flight services within the next five years. However, hundreds of companies or start-ups around the world are developing new prototypes, although companies that are going through the certification process are very few, while the others are still in the design phase. Considering hypothetical sustainable future mobility, all these vehicles will be electric, but there are several issues to be resolved before this can be achieved, and not all of them are necessarily technical. Indeed, the logistics aspect, linked to flight paths, but especially to the places where these machines will be able to land and take off and, above all, recharge, the so-called “vertiports” is still in the preliminary phase. In this regard, DAER is building its own “vertiport” on the roof of one of the new buildings that will house its new laboratories. We hope to make a strong contribution to this revolution in aviation.

MOST received funding from the European Union’s Next-Generation EU programme (NATIONAL RECOVERY AND RESILIENCE PLAN (NRRP) – MISSION 4 COMPONENT 2, INVESTMENT 1.4 – Director’s Decree 1033 17/06/2022, CN00000023).