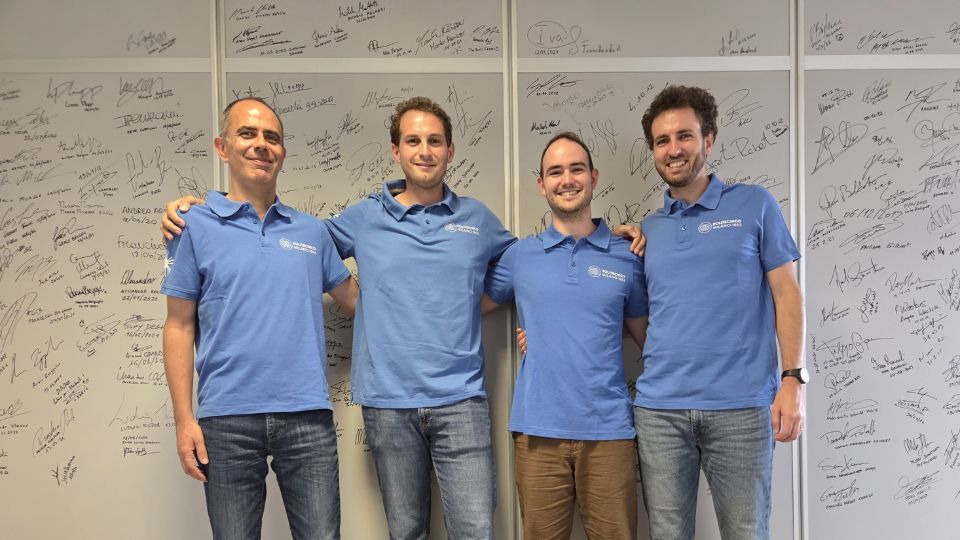

Claudio Somaschini, Associate Professor in the Department of Mechanical Engineering and Head of Aerodynamics in Sport at the Wind Tunnel facility, offers us an insightful look into the world of sport-oriented research. He explains how a lifelong passion for cycling has shaped his professional journey and positioned him at the forefront of performance enhancement for elite athletes. This interview is a unique opportunity to explore the convergence of engineering, science, and sport to understand the crucial role aerodynamic measurements play in achieving exceptional athletic results.

Could you tell us about your professional journey? How did you come to lead aerodynamic testing at the Wind Tunnel?

It all began with my deep-rooted passion for cycling. I competed for 12 years, three of which were at an amateur level, before stepping back just prior to undertaking my bachelor’s degree due to the increasing demands of university.

Cycling training typically involves three to five hours of daily effort, often during the middle of the day, alongside frequent travel for races, making it extremely challenging to balance with academic studies. Few professional athletes manage to complete a university course. However, this passion has remained a constant in my life, passed down from a family deeply immersed in the cycling world.

When did Wind Tunnel testing begin?

Wind tunnel testing (GVPM) started almost 14 years ago. I observed the first trials while working on my thesis under Professor Belloli’s supervision. Since his appointment as Head of the Department of Mechanical Engineering, I have assumed responsibility for all sport-related aerodynamic trials.

Today, our activities at GVPM are highly structured and conducted regularly. Over time, we’ve cultivated enduring relationships with a loyal client base, founded on mutual trust. This enabled us to secure a prominent international position.

Our location in Milan is a significant logistical advantage, given the prevalence of cycle races in Europe. This makes it easier for athletes to access our facility than an Australian wind tunnel. There are three other comparable wind tunnel centres in Europe; however, to our knowledge, ours is the only one operating continuously within a university research context.

We work with a broad range of stakeholders: commercial sponsors, suppliers, professional teams, and all appreciate our impartial stance. Although we may host five different clients over five consecutive testing days, our strict confidentiality policy means we never share, compare, or analyse data across projects. This level of discretion makes us effectively “invisible” and ensures absolute neutrality.

Who comes to GVPM for testing?

We’ve been especially proud of our partnership with the Italian National Cycling Team and CONI (the Italian National Olympic Committee). These partnerships are active in the lead-up to the Olympic Games. Two years ago, in preparation for Paris Olympics, we hosted several days of trials with the national track and time trial teams. This was a significant opportunity to work extensively with female athletes. Although investment and testing in women’s sport remain limited compared to the men’s side, we are beginning to witness a shift. Women’s cycling has seen considerable growth in visibility and participation in recent years. Today, all major men’s professional teams also support women’s squads.

In your view, when might the gender gap in cycling performance support be bridged?

It will take time, but the momentum is building. This year we worked with Colnago, who brought us a male athlete and Elisa Longo Borghini, one of the leading figures in women’s professional cycling and a member of UAE Team ADQ.

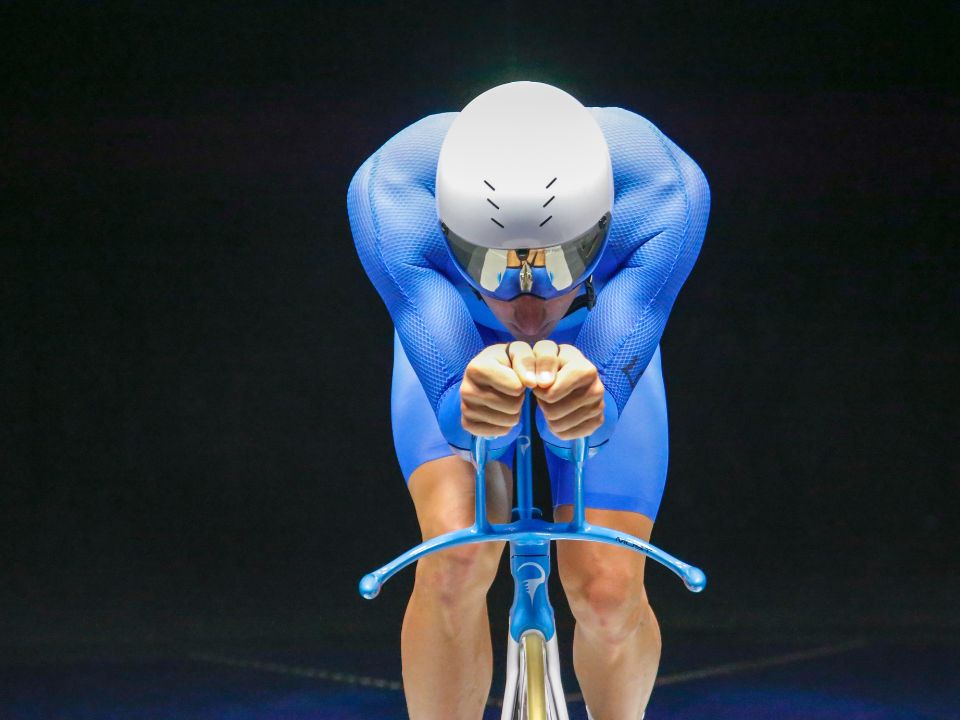

At the recent Opening of the Academic Year, Filippo Ganna was among the guests. We understand he is something of a regular at GVPM. Tell us how the relationship with him and his team started.

Our partnership with Filippo Ganna dates to the early stages of his professional career. We’ve developed a strong working relationship with him, and his support team. His proximity to Milan further facilitates this ongoing partnership. He is without doubt the athlete we have worked with the most.

Beyond working with elite athletes, we maintain close ties with companies, particularly those in Lombardy. Our Wind Tunnel (GVPM) is primarily a research and testing laboratory. We do not provide consultancy services. Our focus is on measuring aerodynamic performance.

The research we conduct is comparative. Athletes and teams arrive with various solutions (positions, components, equipment). We evaluate aerodynamic drag and offer a comparative analysis of different configurations, enabling the identification of the most efficient solution.

Could you describe, perhaps for those less familiar, what a typical day of aerodynamic testing in the wind tunnel looks like?

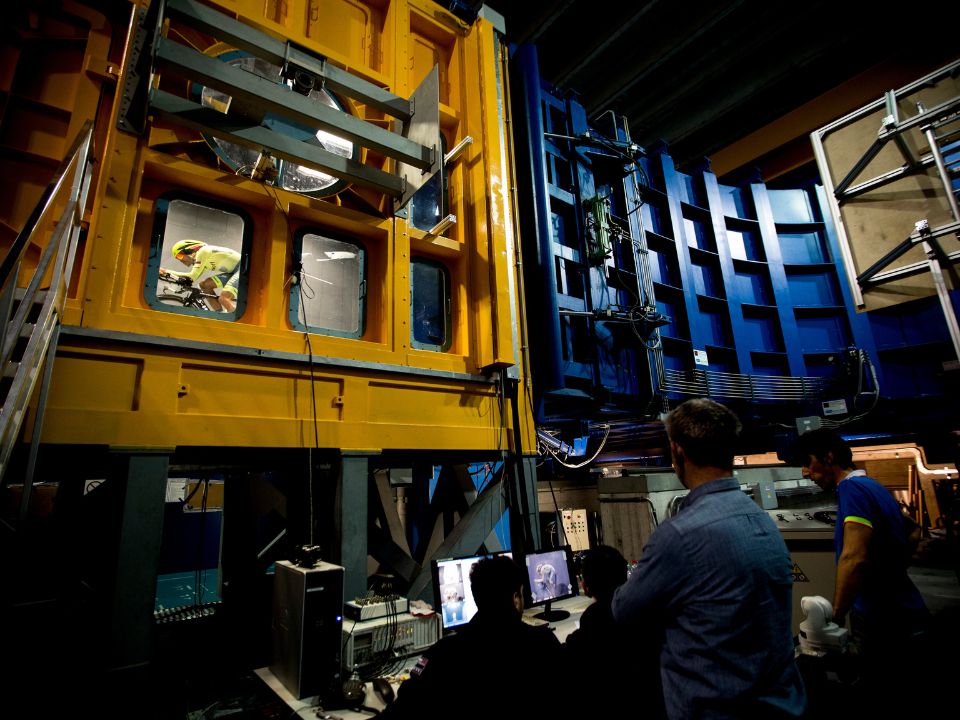

Absolutely. Let’s consider one of the most common scenarios where an athlete arrives to test a range of different configurations. The process begins with securing the bicycle onto a specially designed rig connected to a dynamometer, which measures wind resistance. The athlete, seated on the bike, must maintain a certain level of power output. This is crucial because the posture of an athlete producing power is different from that of a relaxed athlete, and muscle configuration during effort influences aerodynamics.

The athlete arrives, conducts warm-up exercises on our designated setup, and we verify the functionality of all systems. We initiate the preliminary tests with wind simulation to acclimate the athlete to the conditions. Working with someone like Filippo Ganna, who trains in our facility up to three times a year, is different from working with a rider who may be entering a wind tunnel for the first time or whose experience has been limited to other facilities.

Our test chamber is essentially a 4-by-4-metre steel cube. The athlete is alone inside, facing the force and sound of high-powered motors simulating wind. Although managed, this condition necessitates an adaptation period. The athlete can see us through glass panels and is monitored via multiple cameras. A display screen in front of them allows for communication and feedback on posture or positioning. It is a highly controlled environment, but the experience of being isolated with the wind and the noise of the motors is unique.

A typical test session begins with the athlete’s arrival, followed by warm-up, system checks, positioning on the bike without wind, and a baseline weight measurement under static conditions. Once ready, we introduce wind into the chamber. The athlete pedals at the required effort level, and once the airflow stabilises, we take precise measurements.

How are the tests carried out?

Recently, we’ve refined our methodology to include tests across a range of wind speeds and yaw angles. Under actual racing conditions, lateral wind can greatly influence an athlete’s forward speed. If the wind comes from the athlete’s right side, it creates a specific angle of incidence. Scientific studies have helped quantify the probability of such wind angles during competition. We typically focus on angles between 10 and 15 degrees, sufficient to represent many race-day conditions.

The data for all angles measured are subsequently provided to the client. There is software capable of estimating wind conditions on a specific route daily. For example, in the case of a Tour de France time trial, the software uses weather forecasts and course layout to simulate likely wind angles. By combining this predictive data with our aerodynamic measurements, we can help teams select the optimal equipment configuration for that race and those environmental conditions.

Each individual test run lasts around five minutes. After the wind is turned off, the athlete takes a short rest while we analyse the data with them. If the results are promising, we proceed with the next test. This may involve a change in riding position, helmet, handlebars, wheels, or other components, and then we resume the testing process. Variations depend on test objectives.

How does the day end?

At the end of the day, we conduct a thorough comparative analysis of the configurations tested (typically around ten) and establish a performance ranking. One of these configurations is designated as the baseline, serving as the benchmark against which other setups are evaluated. This baseline is repeated periodically throughout the session, often every four configurations. This is crucial, particularly when working with professional athletes who have already fine-tuned their aerodynamic performance. At such advanced levels, the differences between one configuration and another are often marginal. Even something as simple as returning from a lunch break more relaxed can lead to minor variations in results when repeating the same baseline configuration.

What I’ve just described is typical of a full-day session dedicated to elite athletes. More commonly, however, several athletes are scheduled throughout a day at the GVPM. For example, we’ve run tests with the men’s team pursuit squad. In such cases, each athlete is tested individually to refine small details, before moving on to optimise the collective team setup.

The real challenge lies in achieving precise measurements that detect extremely subtle differences, sometimes in the range of just a few grams of drag. Even a small change in head position can significantly impact aerodynamic efficiency. That’s why we use multiple cameras to monitor and record the athlete’s posture, allowing us to detect and evaluate even the slightest adjustments.

We tend to achieve better results with athletes who are familiar with our procedures and the initial setup. To manage these complexities, some clients perform preliminary tests using a dynamic mannequin that mimics pedalling, simulating similar aerodynamic conditions. While this approach is effective for developing or assessing specific components, such as wheels, it cannot fully replace live testing on the athlete.

Thinking back over your years at GVPM, is there a particular moment that stands out for you?

Coming from a family of cycling enthusiasts, I’ll never forget meeting Fabian Cancellara, the Swiss world champion, early in my career. Another unforgettable memory is Alex Zanardi’s visit following the London Paralympics. We had worked with him before the Games, and I vividly recall the excitement and pride when he returned with his medals.

A more recent moment that stands out is Filippo Ganna’s World Championship win by just thousandths of a second. He had been with us shortly before the event, and I recall the exchanges of messages with the team. Last year, I had the chance to meet Filippo again during a Giro d’Italia time trial at Lake Garda. As engineers focused on data and machinery, we rarely experience moments of human interaction. Working with people is a different, fulfilling and rewarding experience.

Have there been more challenging experiences?

One of the more difficult scenarios is when an athlete arrives with a fixed mindset and struggles to trust the data produced during testing. Unfortunately, this happens. That’s why I advise teams to prepare the athlete thoroughly in advance, explaining how the testing works and setting clear expectations for what it involves.

I remember many years ago an athlete’s team was disappointed that the results didn’t show any improvement despite a series of tests. At the level most professionals operate, meaningful gains are extremely hard to come by. The differences can be so small that they fall within the margin of error of even the most precise equipment. For this reason, we inform athletes that differences must fall within our system’s measurement uncertainty. We can’t favour one configuration over another due to differences within our accuracy range, even though they may differ in aerodynamic resistance.

Working with those fluent in our scientific “language” greatly simplifies matters. Two years ago we hosted Australian champion Luke Plapp, followed by his coach, Michele Pinotti, a former Italian cyclist and an engineer.

Was it more difficult?

On the contrary, it was far easier. Interactions between engineers and athletes are often challenging, except with Alex Zanardi, where it was smooth. Looking back, we realised that Alex’s background in motor racing made all the difference. He was accustomed to engaging with technicians and engineers and articulating his sensations in technical terms. Communicating a test result, justifying the need for repetition, or discussing marginal differences is all part of the process. At GVPM, we’ve become well-trained in this area over time.

You clearly have great passion for your work. What does the future hold for you?

I tend to live in the present. In a testing facility, it is difficult to predict which athletes will be present even a few months in advance. However, those who come to GVPM usually return. We work exclusively with high-level professional cyclists. Although we have received enquiries from amateur athletes, we’ve never run tests with them. This is because the process requires continuity and a certain level of experience on both sides to be effective.

Looking to the future, GVPM will remain a vital part of performance optimisation for elite athletes. In today’s cycling world, every detail is scrutinised: shoes, kit, wheels, frame, overshoes, even water bottles. The margins are incredibly small. Fortunately, every athlete is unique, so individual optimisation must always be sought.

Regulations change, making new research opportunities possible in the future. Filippo Ganna’s hour record was set using a bike that complies with track race regulations. Ganna’s record was significant because it surpassed the previous absolute hour record, which had stood for more than 15 years and had been set on a completely bespoke prototype bike, one that would no longer be legal today due to updated safety standards.

In recent years, safety has become a major focus in cycling. Certain riding positions such as sitting on the top tube while descending or riding without hands on the bars, have been outlawed. This is partly because cycling now has such a wide audience, with millions watching. There is a risk that enthusiastic amateurs could try to mimic these professional techniques, and put themselves in danger.

Does GVPM serve any sports beyond cycling?

Over the years we’ve tested a wide variety of disciplines, including skiing, snowboarding, speed skating, skeleton, luge, and ski jumping. We have conducted some trials related to motorcycling, and in the lead-up to Paris, we explored the feasibility of conducting tests for sailing. However, cycling remains our primary area of focus, not least because it continues to attract significant investment, which drives research and innovation.